Automatic antifreeze filling machine

- Keywords:antifreeze filling machine,antifreeze filler,coolant filling machine,snap on coolant vacuum filler,coolant pressure filler,heavy duty coolant vacuum filler,vac u fill coolant machine,engine coolant vacuum filler,antifreeze vacuum filler,best coolant vacuum filler,best vacuum coolant filler,radiator coolant filling machine,snap on coolant filler,antifreeze packing machine

- Application: It is commonly used in the food service,cleaning and specialty chemical,pharmaceutical, cosmetic and personal care industries for various filling projects.

What you can get from us?

-

100% Refund Policy

If the quality is poor or it can’t run your product, we guarantee a 100% full refund for your peace of mind

-

Two years warranty

Any equipment purchased from us comes with a two-year warranty.we provide free replacements and cover shipping for parts under 10kg damaged due to quality issues, not deliberate damage

-

Attentive after-sales service

We promise: all equipment purchased from us is backed by comprehensive after-sales service and lifetime benefits.

-

Timely production and delivery

We oversee the entire process from receiving samples to design and production, providing timely photos and videos to showcase the entire process to ensure the efficiency of equipment production and timely delivery

Parameter:

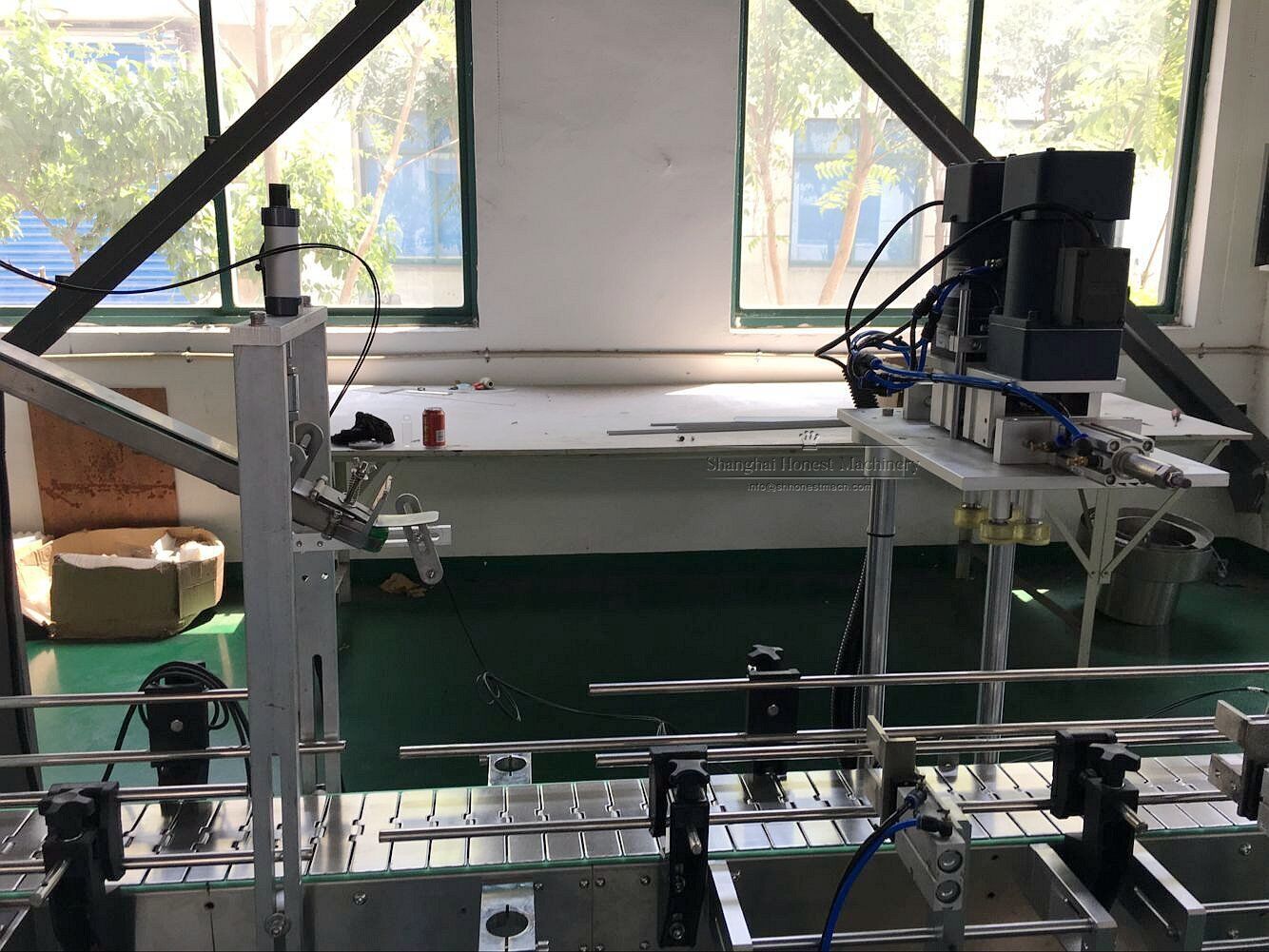

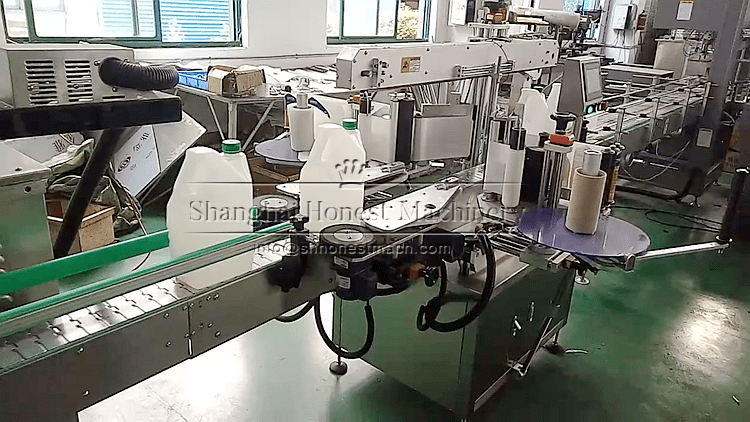

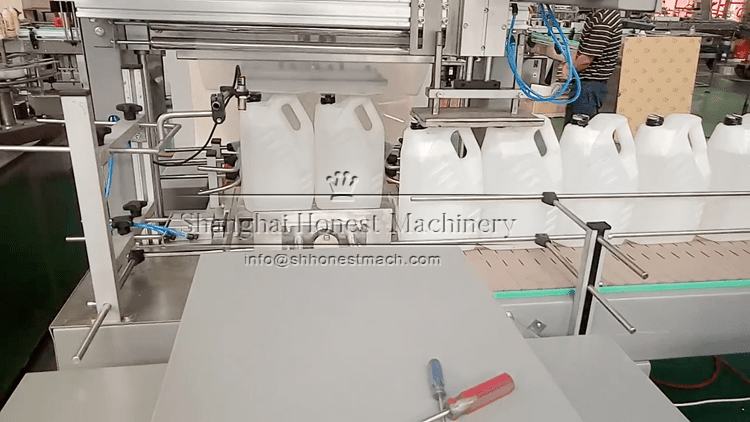

- Model: Automatic antifreeze filling machine

- Filling volume: 500ml-5L(customized)

- Filling nozzles: 1-16 nozzles for your optional(customized)

- Filling speed: 10-100BPM for your optional(customized)

- Filling method: Piston pump for filling with servo motor control

- Filling accuracy: ±1%(according to product)

- Capping rate: ≥99.99%

- Power supply: Single phase 110V/220V,50/60Hz or three phase 380V/440V 50/60Hz(customized)

- Total dimension: 2300mm*1650mm*2250mm(customized)

Highlight:

1.It use piston pumps for filling, suitable for materials of different viscosities.

2.With servo motor control, it can automatically adjust the filling volume, making it convenient for customer operation and use

1.All connections adopt quick release joint,easy to dismantle and maintain,reduce the cost of the use and maintenance,save the time

Related Products:

FAQ:

Machine is customized,different speed and containers,the machine we suggest for you and price will be different.there are at least 2 items you need share with us as follow:

1.We hope you can send the picture of your containers to us(with cap and label)

2.We hope you can tell me the speed you asked for?how many bottles per hour is suitable for you,for example,2000 bottles per hour or else?

We hope you can send these 2 items information to our email: rich@shhonestmach.com ,then we can double confirm to suggest most suitable machine line for you and send the video,solution,drawing and right quotation to you within 48 hours

Machine is customized.normally speaking,it will take about 30-50 days to finished the machine when we get the container sample and deposit(30%) from customer,the specific production time needs to be provided according to the corresponding production schedule based on the different equipment requirements of the customer.

For more details, please consult our sales representative. We can also offer different transportation options for customers to choose from, such as shipping by by air, by sea,by rail, or express delivery. the transportation method can be flexibly adjusted according to the customer’s specific requirements.

For first-time customers, we will also strive to provide free shipping services whenever possible

Any equipment purchased from us comes with a two-year warranty. If the quality is poor or it can’t run your product, we guarantee a 100% full refund for your peace of mind

1.Within two years, we provide free replacements and cover shipping for parts under 10kg damaged due to quality issues, not deliberate damage

2.If the equipment fails to meet quality standards or run your product, we assure a 100% refund. Shop with confidence, use with peace of mind

Our equipment is simple to install and operate; over 90% of customers can install and use the equipment based on the provided materials.

1.We provide coded stickers on different parts of the equipment to guide customers on how to connect the machine and circuits.

2.Disassembly and installation videos for the equipment are promptly provided to customers, demonstrating how to install the equipment and aiding in their understanding

3.Manuals in different languages and circuit diagrams of the equipment are provided according to customer’s requirements

4.We offer real-time assistance through platforms like WeChat, WhatsApp, or Zoom to help customers resolve any sudden or unfamiliar issues

5.Once the equipment is tested, we invite customers to our factory at any time for acceptance and learning. We also support third-party testing and inspection at the customer’s request.

6.If needed, we can arrange for engineers to install and debug equipment directly at the customer’s factory. However, round-trip airfare, accommodation, and meals will be borne by the customer

Let’s start this journey together!

Revolutionize your production with our bottling machines!Share your needs and we’ll be in touch with a tailored quote within 48 hours.

SEND BELOW INQUIRY